Graphene, a two-dimensional honeycomb lattice of carbon atoms, has made waves in science and technology circles. Last week, I gave a brief overview of the history of the stuff and why it’s special. This week, I’d like to continue the story by talking about applications. Unfortunately for us—and fortunately for society as a whole—graphene has spawned so many new technologies that it’s impossible for me to discuss them all. So instead, I thought I’d talk a single application that has personal value to me.

As an undergraduate student, I spent two years in a laser lab studying graphene’s applications in ultrafast optics. Today, I’ll tell you part of that story.

Graphene and Me

I had my first run-in with graphene in the spring of 2010. I had just started working in quantum optics under Professor Thomas Schibli at the University of Colorado. Professor Schibli and his graduate student, Chien-Chung Lee, were interested in using graphene as a saturable absorber to make ultrafast pulsed lasers. (A saturable absorber is a material that becomes transparent when sufficiently bright light shines on it.) Because graphene responds to electrical signals incredibly quickly, it can respond to a laser pulse equally quickly.

Most saturable absorbers only work for one color of light. However, graphene works for all colors of light. In fact, it absorbs light so strongly that, even though it’s only one atom thick, we can see it with the naked eye. The image below shows a graphene sheet made in the Schibli lab on a laser mirror.

We made our own graphene in-house, and it was my job to develop a production method that worked best for ultrafast lasers.

Growing the Wonder Material

Graphene was first made with the “Scotch tape method,” which involves pulling graphene flakes off of graphite blocks with—you guessed it—adhesive tape. The Scotch tape method produces very high quality graphene, but not very much of it. For laser physics, we needed to scale things up a bit.

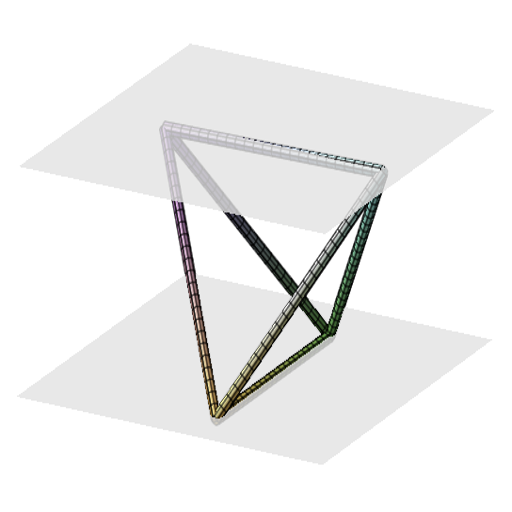

We followed the example of Bae et al., who had been funded by Samsung to develop a method for chemically growing very large sheets of graphene. We used a technique called chemical vapor deposition (CVD): First, we put a piece of pure copper foil in a very high-temperature, low-pressure chamber. The air pressure around the foil is one one-millionth of an atmosphere and the temperature is one thousand degrees Celsius. We then blow tiny amounts of methane and hydrogen gas over the copper foil. Methane is one carbon atom and four hydrogen atoms, and the copper foil catalyzes a reaction that causes the molecule to break apart. The carbon atoms deposit on the copper in a hexagonal pattern, leaving the hydrogen to be blown away. Because copper is the catalyst, the reaction stops when the foil is covered up—in our case, when a single layer of carbon atoms has been deposited. The figure below shows the Schibli group’s CVD setup. The orange thing is the vacuum pump which reduces the pressure in the glass tube. The white thing is the furnace.

After we grow the graphene, we’re faced with a problem: How precisely do we get such a delicate sheet off the copper wire without damaging it? In the Schibli lab, we followed the technique of Li et al., who etched their copper away with acid. The transfer method is a bit more complicated than that, because the graphene can’t survive on its own and because the acid must be cleaned off with great care. However, in the interest of space, I’m going to skip these details.

Measurements

After growing and separating out the graphene, we would observe the flakes in an electron microscope and measure how the amount of light it absorbed varied with intensity. The figure below shows a pair of such measurements. On the left, I plot the percent of light absorbed by a single layer of graphene as a function of the light’s intensity. (As you can see, the graphene burns before we can shine enough light on it to reach its maximum transparency.) On the right is an image of the same graphene under a scanning electron microscope.

Because the graphene burned at the highest intensities, we weren’t able to use it to generate the pulses in a laser. However, graphene still proved itself useful; this research led to the development of a tool called an electro-optic modulator. But that’s a story for next week.

Related Articles

- All of my research in graphene involved pulsed lasers. I wrote an article on lasers and an article on pulsed lasers. You might find them interesting.

- If you missed my introduction to graphene last week, you might want to check it out here.

- Graphene is special because it’s a semiconductor with a band structure. You can find my article on band structure here.

- If you’re brave, you can find my undergraduate honors thesis on graphene here. I try to introduce specialized topics, so it should be accessible to someone who remembers their college physics courses.

- I’m a co-author on a paper the Schibli group published on the saturable absorption in graphene. Sadly, it’s behind a paywall, but can find it here.

One thought on “Graphene and Me: My Brush with the Wonder Material”

Comments are closed.